Autoscanning spotlight. Should we use the bimetal technology?

We have participated to an interesting industrial R&D project, led by a student group. The idea was to realize a spotlight, which could automatically scan the surface of a presentation board. The bimetal technology appeared to be relevant: then needed mouvement is actuated by the deflection of a bimetal, which is heated by a thermistance (heating resistor).

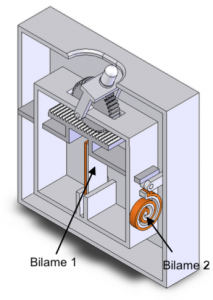

Description

Intended to professional or amateurs users, this spotlight is made to illuminate boards or graphic presentations of various sizes (100x100mm to 594x841mm).

Concerning the mechanical part of the device, the students explored several avenues, one of which is using bimetals for the spotlight motion (horizontal and vertical movement for he LED light). This technology is adapted, as the bimetal, once heated, operates a gradual and repetitive mouvement.

The solution has been selected, as the study was in good progress, and as everyone wanted to explore this simple and low cost technology. Two other solutions have been mentioned, but not selected:

- the use of stepper motor (presumably the most common way to deal with accurate moves),

- the use of shape memory alloys (a not well mastered technology).

L’étude

The study of mechanical transfer led to a double system rack and pinion + spiral bimetal, in order to ensure the rotation in 2 directions, with a space near the slot of the rack, to avoid an over-center of the bimetal while deflecting. The requested effort necessitated a double-bimetal.

Whereas, the thermal study led to a solution with a thermal resistor, which is the most common way to heat an element.

A particular resistor, the CTP (variable resistor according to the temperature, generally used as a thermal sensor) can be used as a heating resistor, when it is powered by a fixed supply. It will be selected for our project, as it is simple to implement.

However, the following hypotheses have been eliminated: use of a solenoid (too complicated) or direct heating of bimetal with current Joule effect (bad conductivity).

However, the following hypotheses have been eliminated: use of a solenoid (too complicated) or direct heating of bimetal with current Joule effect (bad conductivity).

Conclusion

This study shows that the bimetal technology is relevant to control small or big movements, with an acceptable effort.

The bimetal, which is generally used as thermal “circuit breaker” (thermostat) quite ensures the function of a mechanical actuator, if we artificially heat it.

The translation or rotation movement (according to the cantilever or spiral bimetal forming), is simply operated by the thermal deflection of this on, replacing a generally complex mechanism.